|

Francois Robitaille |

|

||||||||||||

|

|

|||||||||||||

|

Biographic Information |

|||||||||||||

|

|

and Research Interests |

||||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

Processing & Performance: Technical Textiles |

|||||||||||||

|

|

|

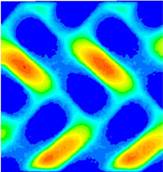

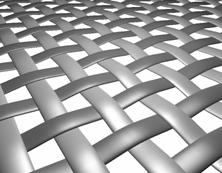

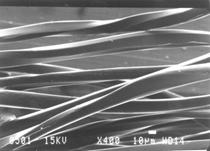

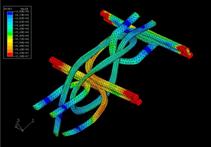

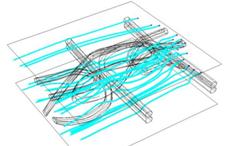

Part of my research work

deals with predictive modelling of the processing and performance properties

of technical textiles. This work is based on a geometric modelling formalism

that I proposed. That formalism has a unique characteristic: it can model the

geometry of virtually any textile in one single way, using the same mathematical

tools. Therefore, subsequent models – sets of equations – that are developed

to predict physical properties can be applied to any textile, regardless of

its manufacturing process. The geometric modeller TexGen

was implemented in collaboration with colleagues at |

|||||||||||

|

|

|||||||||||||

|

Processing & Performance: Polymer Composites |

|||||||||||||

|

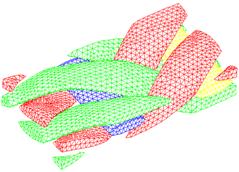

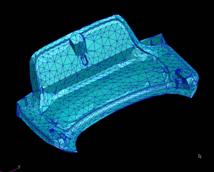

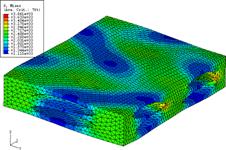

One of the applications

of the above work has to do with the design and manufacturing of composite

parts. Simulation software for the injection of resin through textile

preforms has been around for many years; similarly, industrialists now have a

good grasp of design for composite materials using finite element. In both

cases meaningful simulations require accurate and extensive data: either fields

of local permeability tensors, local stiffness tensors and/or local failure

envelopes. As such data cannot realistically be obtained from measurement for

any prospective combination of industrial fabrics, the objective is to go one

step further in simulation and provide this data through predictive numerical

methods, including factors such as the variability. These ‘sub-simulations’ require

methods where speed is much increased. |

|

|

|||||||||||

|

|

|||||||||||||

|

Manufacturing of Large Composite Structures |

|||||||||||||

|

|

|

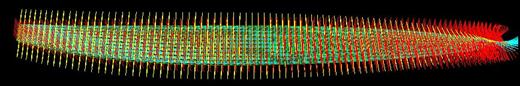

One industrial

application of the above for which I have much interest is the manufacturing

of large composite parts. My experience of this, including support for the

production of a composite lorry trailer, shows that usage of extensive data

is an absolute requirement to accurate or useful simulations. |

|||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

Multi-Scale, Multi-Physics Modelling of Materials |

|||||||||||||

|

|

|

One key aspect of the

behaviour of technical textiles and textile preforms used for composite manufacturing

is that their finer geometry strongly affects other properties such as the

permeability or heat transfer characteristics. In turn these properties behave

more or less as functions of each other, with say the permeability to gas

affecting heat transfer through the textile. As the finer geometry of

textiles is generally not set, predicting any property often requires multi-physics

modelling. |

|

||||||||||

|

|

|||||||||||||

|

Novel Applications for Technical Textiles |

|||||||||||||

|

|

|

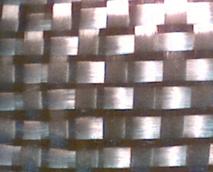

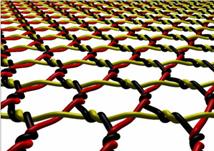

One of the long-term aims

in developing capabilities to predict the properties of virtually any technical

textile is to enable true computer-based design of novel solutions to any

problem involving these engineering materials. This ongoing work aims at

simulating actual industrial materials and is not limited to generic, simpler

forms such as dry weaves. |

|

||||||||||

|

|

|||||||||||||

|

Materials and Design |

|||||||||||||

|

|

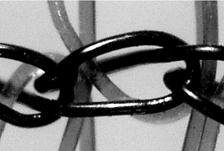

The above work is part of

a strong interest in materials, design and manufacturing. Whilst my research

interests focus on numerical modelling and property measurement for technical

textiles and textile composites, upon doing design I give equal consideration

to other materials solutions and the numerous ways in which different

materials system may best interact towards stated objectives for each

application. Many important considerations such as joining, shaping, stress

transfer etc. must be looked into when designing multi-materials solutions, which

in themselves constitute important and challenging research areas. |

|

|||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

Individuals with an interest towards post-graduate

research on related areas leading to an MScA or PhD

are welcome to contact me via email.

Note that you must also apply electronically to the Ottawa-Carleton

Institute for Aerospace and Mechanical Engineering, which manages all

graduate applications in Mechanical Engineering for the When applying to OCIMAE

please specify my name as your preferred supervisor, so that your file will

reach me directly in addition to being directed to a candidate selection

list. You can specify up to three preferred supervisors if you identify other

areas of interest to you. |

|||||||||||||

|

|

|||||||||||||

|

|

|

|

|

||||||||||

|

|

|

|

|

||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

Articles in refereed

journals: 1. Use of resin transfer moulding simulation to predict flow, saturation

and compaction in the VARTM process. 2. The effect of interlaminar toughening strategies on the energy

absorption of composite tubes. Warrior NA, Turner TA, Robitaille F, Rudd

CD. Composites Part A - Applied Science

and Manufacturing, 35(4),

431-437, 2004 3. Automatically generated geometric descriptions of textile and

composite unit cells. Robitaille F, Long AC, 4. Effect of resin properties and processing parameters on crash energy

absorbing composite structures made by RTM. Warrior NA, Turner TA,

Robitaille F, Rudd CD. Composites Part

A - Applied Science and Manufacturing, 34(6), 543-550, 2003 5. Geometric modelling of textiles for prediction of composite

processing and performance characteristics. Robitaille F, Long AC, Rudd

CD. Plastics, Rubber and Composites,

31(2), 66-75, 2002 6. Effect of resin formulation on crash energy absorbing composite

structures made by RTM. Turner TA, Robitaille F, Warrior NA, Rudd CD,

Cooper EJ. Plastics,

Rubber and Composites, 31(2),

49-57, 2002 7. Effects of fibre architecture on reinforcement fabric deformation.

Long AC, Souter BJ,

Robitaille F, Rudd CD. Plastics, Rubber

and Composites, 31(2), 87-97,

2002 8. Permeability prediction for industrial preforms. Robitaille F,

Long AC, Rudd CD. Plastics, Rubber and

Composites, 31(6), 238-248,

2002 9. Mechanical modelling of in-plane shear and draping for woven and

non-crimp reinforcements. Long AC, Robitaille F, Souter

BJ. Journal

of Thermoplastic Composite Materials, 14(4), 316-326, 2001 10. Geometric modelling of industrial preforms: warp-knitted textiles.

Robitaille F, Clayton BR,

Long AC, Souter BJ, Rudd CD. Journal of Materials:

Design and Applications – Proceedings of

the IMechE Part L, 214, 71-90, 2000 11. Geometric modelling of industrial preforms: woven and braided

textiles. Robitaille F, Clayton BR, Long AC, Souter BJ, Rudd CD. Journal of Materials: Design and Applications – Proceedings of the IMechE Part L, 213, 69-83, 1999 12. Effect of fibre architecture on deformation during preform

manufacture. Long AC, Souter BJ, Robitaille F, Rudd CD. Advanced Composites Letters, 8(6),

333-344, 1999 13. Compaction of textile reinforcements for composites manufacturing.

III: Reorganization of the fiber network.

Robitaille F, Gauvin R. Polymer Composites, 20(1),

48-61, 1999 14. Compaction of textile reinforcements for composites manufacturing.

II: Compaction and relaxation of dry and H2O-saturated woven

reinforcements. Robitaille F, Gauvin R. Polymer Composites, 19(5), 543-557, 1998 15. Compaction of textile reinforcements for composites manufacturing. I:

Review of experimental results. Robitaille F, Gauvin

R. Polymer Composites, 19(2), 198-216, 1998 16. Analysis of the vacuum infusion moulding process: 1. Analytical

formulation. 17. Influence of stochastic fibre angle variations on the permeability

of bi-directional textile fabrics. Endruweit A,

Long AC, Robitaille F, Rudd CD. Submitted to Composites Part A: Applied Science and Manufacturing, 2004 18. Comparisons of novel and efficient approaches for permeability

prediction based on the fabric architecture. Wong CC, Long AC, Sherburn M, Robitaille F, Harrison P, Rudd CD. Submitted

to Composites Part A: Applied Science

and Manufacturing, 2004 Contributions to

refereed conference proceedings: 19. Geometric

pre-processor for the calculation of physical properties of textiles. Sherburn M, Robitaille F, Long AC, Rudd CD.

Proc. ISC-2004 (Industrial Simulation Conference, Spn. EUROSIS: European Society

for Modelling and Simulation Technology) 20. Predictive

modelling and performance properties of textile composite unit cells: current status and perspectives. Robitaille F, Long AC, Sherburn

M, Wong CC, Rudd CD. Proc. ECCM-11 (European Conf. on Composite Materials, Spn.

ESCM: European Society for Composite Materials) 21. Dependence

of permeability variations on the textile structure. Endruweit

A, Long AC, Robitaille F, Rudd CD. Proc. ECCM-11 (Details above) 22. Investigation

of a novel vacuum bag design for the vacuum infusion process. Ragondet A, 23. Fabrication methods for crash energy absorbing composite structures.

Warrior NA, Rudd CD, Turner TA, Robitaille F. Proc. 25th SAMPE-Europe Annual Conf. (Spn. Society for the Advancement of Material and Process

Engineering), Paris, 24. Modelling the effect of fibre architecture on permeability for

textile preforms. Long AC, Wong CC, Sherburn

M, Robitaille F. Proc. 25th SAMPE-Europe Annual Conf. (Details above) 25. Systematic predictive permeability modelling using commercial CFD and dedicated calculation method. Robitaille F,

Long AC, Wong CC, Rudd CD. Proc. ICCM-14 (Intl. Conf. on Composite Materials, Spn.

SME: Society of Manufacturing Engineers), Also published as Technical Paper EM03-377, Society of Manufacturing

Engineers. 26. A systematic study of the mechanical properties of textile

composite unit cells based on geometric modelling. Crookston J,

Robitaille F, Long AC, 27. Modelling strategies for textile composites. Long AC,

Robitaille F, Rudd CD, Jones IA. Proc. ICCM-14 (Details above) Also published as Technical Paper EM03-371, Society of Manufacturing

Engineers. 28. Analytical and numerical studies into the vacuum infusion process:

in-plane flow in compressible porous media. 29. Analytical and numerical modelling of vacuum infusion. Long AC,

30. Automated generation of tow envelopes and inter-tow volumes for

composite unit cell modelling. Robitaille F, Long AC, Jones IA, Crookston JJ, Rudd CD. Proc. TexComp-6 (Intl. Conf. on Textile Composites, Spn.

KULeuven), 31. Experimental investigation and modelling of the vacuum infusion

process. Ragondet

A, 32. Use of resin transfer molding simulation to

predict flow, saturation and compaction in the VARTM

process. 33. Effect of the processing parameters on crash energy absorbing

composite structures made by RTM. Turner TA, Warrior NA, Robitaille F,

Rudd CD, Cooper EJ. Proc. ICMAC 2001 (Intl. Conf. on Manufacturing of Advanced Composites, Spn. IoM: The 34. TEXFLOW: software for efficient permeability characterisation of industrial

preforms. Robitaille F, Long AC, Rudd CD, Souter

BJ. Proc. ICMAC 2001 (Details above) 35. Permeability prediction for industrial textile preforms. Robitaille

F, Long AC, Rudd CD. Proc. PPS-17

(17th Annual Meeting of the

Polymer Processing Society, Spn. PPS), 36. Permeability prediction for sheared, compacted textiles during liquid

composite moulding. Long AC, Robitaille F, Souter

BJ, Rudd CD. Proc.

ICCM-13 (Intl. Conf. on Composite Materials, Spn.

SME: Society of Manufacturing Engineers), 37. A fabric mechanics approach to draping of woven and non-crimp

reinforcement. Long AC, Souter BJ, Robitaille F. Proc.

15th ASC Annual Technical Conf. (Spn. American Society for Composites), 38. Prediction of reinforcement permeability from a textile geometric

model. Long AC,

Robitaille F, Souter BJ, Rudd CD. Proc.

TexComp-5 (Intl. Conf. on Textile

Composites, Spn. KULeuven),

39. Permeability

modelling of industrial preforms: simulations and practical aspects. Robitaille

F, Long AC, Souter BJ,

Rudd CD. Proc. ECCM-9 (European Conf. on Composite Materials, Spn.

ESCM: European Society for Composite Materials) 40. Modelling

the influence of reinforcement architecture on formability. Souter BJ, Long

AC, Robitaille F, Rudd CD. Proc. ECCM-9 (Details above) 41. Applications of fiber architecture modeling for engineered preforms. Long AC, Robitaille

F, Souter BJ, Rudd

CD. Proc. 1999 SAMPE/ACCE/DOE

Automotive Composites Conf. and Exhibition (Spn.

Society for the Advancement of Material and Process, US Department of Energy)

Detroit, MI USA, September 1999 42. The influence of fabric mechanics on draping. Souter BJ, Long AC, Robitaille F, Rudd CD. Proc

ICAC-99 (Intl. Conf. on

Automated Composites, Spn. IoM: The 43. Effects of fibre architecture on deformation during preform

manufacture. Long AC, Souter

BJ, Robitaille F, Rudd

CD. Proc. ICCM-12 (Intl. Conf. on

Composite Materials, Spn. SME:

Society of Manufacturing Engineers), 44. A predictive model for drape and flow analysis of industrial textile

preforms. Robitaille F, Souter BJ, Long AC, Rudd CD. Proc.

ICAC-98 (Intl. Conf. on

Advanced Composites, 45. The measurement of in-plane

permeability for sheared preforms. Robitaille F, Long AC, Rudd CD,

Souter BJ. Proc. CADCOMP-6 (Computer Methods in Composite Materials), 46. Compaction and relaxation

of dry and saturated textile reinforcements: theory and experimental results.

Robitaille F, Gauvin R. Proc. ECCM-8 (European Conf. on Composite Materials, Spn. ESCM: European Society for Composite Materials), 47. A geometrical model for

textile preforms. Robitaille F, Souter

BJ, Long AC, Rudd CD. Proc.

19th SAMPE-Europe Annual Conf. (Spn.

Society for the Advancement of Material and Process Engineering), Paris, 48. Compaction

properties of textile reinforcements in flexible-wall molding and other

RTM-derived processes. Robitaille F, Gauvin

R. Proc. ICCE-4 (Intl. Conf.

Composites Engineering, Spn. Intl. Community

for Composites Engineering), 49. Effect of

the fluid on the compaction properties of fiber reinforcements in composites

processing. Robitaille F, Gauvin R. Proc. ANTEC-97 (SPE Annual Technical Conference,

Spn. Society of Plastics Engineers), 50. Optimum

consolidation of prepreg thermoplastic composites

using statistical experiment-planning methods. Vovor

T, Robitaille F, Gauvin R. Proc. SAMPE1994 (39th Symposium & Exhibition, Spn.

Society

for the Advancement of Material and Process Engineering), Contributions to

non-refereed conference proceedings: 51.

Analysis of the flow enhancement medium used in the vacuum infusion process. Ragondet A, Robitaille F,

Long AC, Rudd CD. Proc. Comptest 2003 (Intl. Conf. Composites Testing

and Model Identification, Spn. ENSAM), 52. Modelling the vacuum infusion of

composite materials. 53. Experimental

investigation on the vacuum infusion process. Ragondet

A, Correia N, Robitaille F, Long AC, Rudd CD. Proc. FRC-9 2002, (Intl. Conf. Fibre

Reinforced Composites, Spn. IMechE

& IoM), 54. Geometric

description of woven and warp-knitted industrial reinforcements for the

calculation of preform deformation and flow properties. Souter BJ,

Robitaille F, Long AC, Rudd CD. Automotive

Composites Workshop 98, Spn. IoM, Brands 55. Effet

du fluide sur les propriétés en compaction des renforts textiles pour pièces

composites. Robitaille F, Gauvin R. Proc.

CANCAM-97 (Congrès canadien de

mécanique appliquée), Quebec City, Canada, June 1997 Co-authored book chapters: 56. Modelling of textile reinforcements. Chapter co-authored by Verpoest I, Lomov SV, Robitaille F for book Design and Manufacture of Textile Composites, currently edited

for Woodhead Publishing UK by Prof. AC Long, 57. Mechanical analysis of textiles. Chapter co-authored by Boisse P, Long AC, Robitaille F for book Design and Manufacture of Textile

Composites, currently edited for Woodhead

Publishing UK by Prof. AC Long, PhD thesis supervised

(completed and successfully defended): 58. Analysis of the vacuum infusion moulding process, NC Correia, PhD thesis, School

of Mechanical, Materials, Manufacturing Engineering and Management,

University of Nottingham, UK, July 2004 Participation in

product development and industrial R&D activity: 59. Draping of the RoadLite demonstrator.

Robitaille F, Long AC, 60. Permeability measurements on F3P preforms

for Aston Martin Vanquish side panels. Robitaille F, Ragondet

A, Rudd CD. Technical report on measured data required for moulding

simulations of automotive composite body panels. Prepared for Jeff Dahl &

Ken Kendall, Ford Research Labs, 61. Simulation of the impregnation of super-conducting magnet coils. Part

2: Interim report. Robitaille F, Earls T. Technical report on simulations

of resin infusion for magnet coils used in magnetic resonance imaging

devices. Prepared for Graham Knight, Oxford Magnet Technology plc, Whitney,

OX 62. Simulation of the impregnation and curing of super-conducting

magnet coils. Part 1: Feasibility study. Robitaille F, Hargreaves DM, Long AC, Rudd CD, Wright NG. Technical

report on simulations of resin infusion for magnet coils used in magnetic

resonance imaging devices. Prepared for Graham Knight, Oxford Magnet

Technology plc, Whitney, OX 63. Simulations of the manufacturing of structural composite parts for

Aston Martin Vanquish. Robitaille F, Rudd CD, Warrior NA, Long AC.

Technical report on the design of injection gates for moulds used in

production of automotive composite parts. Prepared for Ken Kendall, Ford

Research Labs, Software development: 64. TexGen,

Textile Geometry Modelling Software. Shared intellectual property rights

with Long AC, Rudd CD, Sherburn

M. Programming by |

|||||||||||||

|

|

|||||||||||||

|

Collaborations

and Sponsors |

|||||||||||||

|

|

|||||||||||||

|

|

|

||||||||||||

|

|

|||||||||||||